In the fast-paced world of transportation, ensuring passenger safety at train stations and transit hubs is paramount. One crucial component in achieving this safety is the use of a platform gap filler. This innovative solution is designed to bridge the dangerous gap between the station platform and the train, minimizing the risk of accidents and enhancing passenger convenience.

Durability and Resilience: Rubber is known for its exceptional durability and elasticity. Rubber platform gap fillers are crafted to withstand heavy foot traffic and extreme weather conditions, ensuring long-lasting performance without the need for frequent replacements.

Enhanced Safety: The primary benefit of installing platform gap fillers is the increased safety they provide. They prevent falls and injuries that can occur when stepping over the gap, making them an essential safety feature for all age groups, particularly children, the elderly, and those with mobility challenges.

Easy Installation and Maintenance: These gap fillers are not only effective but also easy to install and maintain. They can be quickly integrated into existing infrastructure with minimal disruption to daily operations, and their maintenance is straightforward, requiring only regular checks and basic cleaning.

Customizable Solutions: Understanding that no two station platforms are exactly alike, manufacturers offer customizable rubber platform gap fillers. They can be tailored to fit specific measurements and needs, ensuring a perfect fit that further enhances safety and functionality.

While primarily used in train stations, rubber platform gap fillers have versatile applications. They can be effectively used in bus depots, ferry terminals, and even loading docks, wherever there is a need to safely and efficiently bridge a gap in a transportation or cargo-handling environment.

S.K. Polymer is proud to be the first company in Thailand to develop the “Platform Gap Filler” (PGF) to enhance passenger safety. This innovative solution prevents accidents by filling the gap between trains and platforms, ensuring safer travel for people of all ages, including those with disabilities.

Our PGF has been successfully implemented in Thailand’s Airport Rail Link, as well as in leading transportation systems in the United States and Norway.

At S.K. Polymer, we are dedicated to pioneering safety innovations that make global transportation more accessible.

Gap Filler from SKP is designed and engineered to endure heavy weights and support wheelchairs.

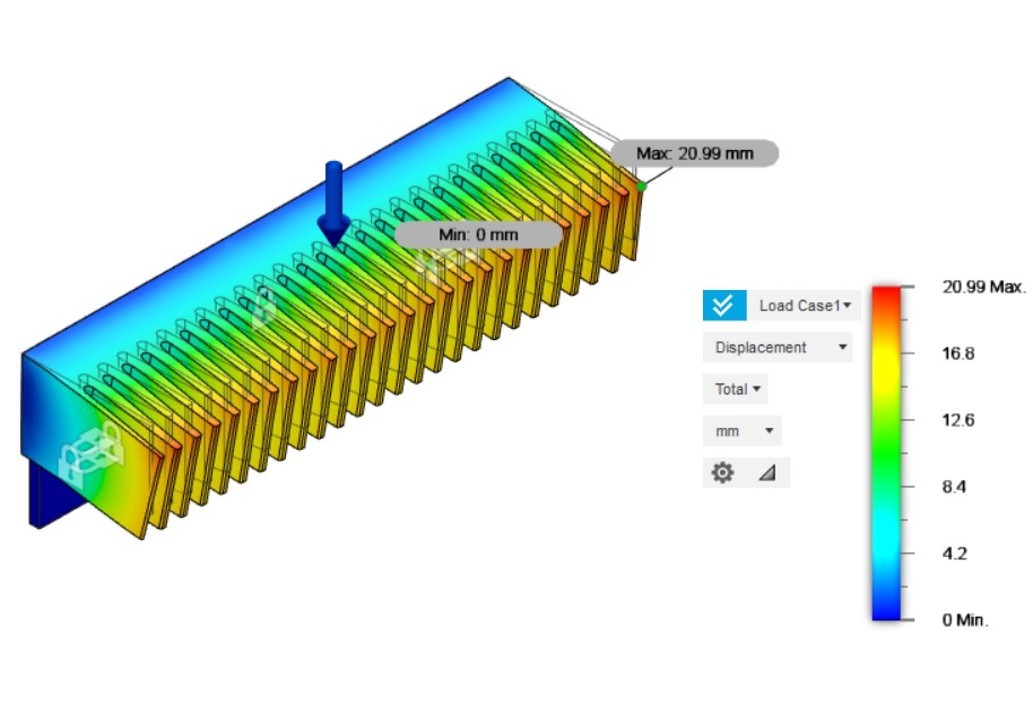

Finite Element is finely used in the design method.

Usability Test (Load test & Fatigue test)

results in weight bearing up to 200 kg/cm2

Varieties of mounting sizes to suit platform configuration. The tooling can be customized for molding different widths of the gap fillers. The steel plate height can also be adjusted.

SKP Platform Gap Filler

Mass-transit trains’ Platform Gap Filler is designed and engineered to endure heavy weights, and support wheel-chair users.

Its material, Chloroprene Rubber (CR) Natural Rubber (NR) , withstands sunlight, ozone, extreme climate, oil, and many other chemical substances. It is also very durable and flame-retardant.

– Designed and engineered to endure weight 200 kg/cm2

– withstands sundlight, ozone, extreme climate

– flame-retardant

We designed a specialized Platform Gap Filler for the Utah Transit Authority (UTA) in the USA to address the unique challenges of Utah’s railway stations. Our solution is engineered to endure the region’s harsh winters and withstand the corrosive effects of salt used for ice melting.

This project demonstrates S.K. Polymer’s expertise in developing customized safety solutions for railway systems, ensuring reliable performance even in the most demanding environments